.png)

.jpg)

.jpg)

The size of the single grain diamond selected for dressing

| Grinding Wheel Diameter (mm) | Diamond (ct) |

| 200 | 0.2 - 0.3 |

| 200 - 400 | 0.3 - 0.5 |

| 400 - 600 | 0.5 - 0.8 |

| 600 - 800 | 0.8 - 1.2 |

| 800 | 1.0 - 1.5 |

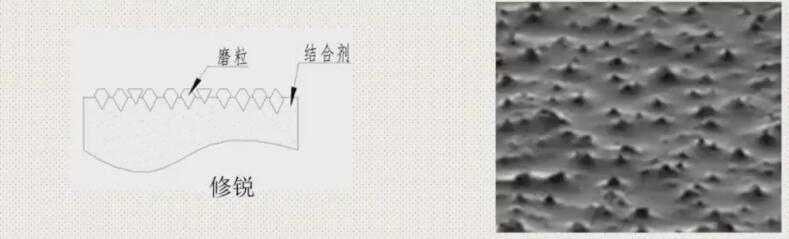

► Multi - Point Diamond Dresser

single-point diamond pen, with high price, and even the need to renovate and other shortcomings

The multi-point diamond dressing tool has small diamond particles and a large number, and the surface quality fluctuation of the grinding wheel is small, the dressing is relatively stable, and the cost is low.

Types:

► Rotary Diamond Dresser

Features

The contact area is large. The outer surface of the grinding wheel coincides with the outer contour of the dressing wheel.

The truning efficiency is high, mainly used for mass production.

High precision (thread, gear, bearing channel, corrugated roller, blade groove, etc.)

The service life of the dressing wheel is long. Usually the roller life can reach more than tens of thousands of times.

Rotary diamond dressers are divided into profile and form rolls (depending on the type of abrasive layer profiling)

.jpg)

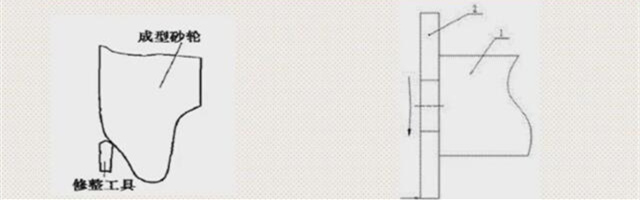

Diamond Profile Dressing Rolls

* Profiling of the grinding wheel along the desired contour by moving the diamond dressing roller

* The profile of the grinding wheel is created by a CNC controlled process that moves the rotating form roll along the target contour

* Form rolls are not restricted to a specific workpiece but can be used flexibly

.jpg)

Diamond Form Dressing Rolls

* Profiling of the grinding wheel in only one operation using the plunge-cut dressing method

* Usually the profile of the roll corresponds precisely to that of the workpiece

* Extreme accuracy, even with highly complex profile contour